Carbide burrs have exceptional durability, versatility, and cutting performance. These burrs are produced from ultra-hard tungsten carbide, enabling them to cut via a wide range of materials, including metals, plastics, wood, and much more. The initial properties of carbide make our burrs exceptionally wear-resistant, making certain they maintain their sharpness and effectiveness as time passes.

Explore Our Extensive Collection:

– Single Cut Carbide Burrs: Great for fine deburring, shaping, and engraving tasks. The one cut pattern generates smaller chips for smoother finishes.

– Double Cut Carbide Burrs: Made for faster material removal that has been enhanced operator control. The double cut pattern produces smaller, more manageable chips, reducing clogging.

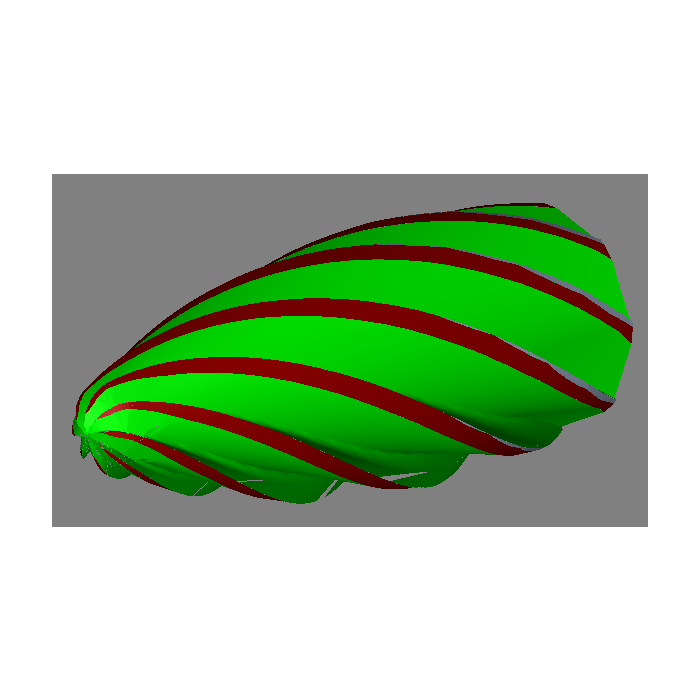

– Aluminum Cut Carbide Burrs: Suitable for softer materials like aluminum, these burrs prevent loading and still provide clean cuts without material buildup.

– Diamond Cut Carbide Burrs: Engineered for that toughest tasks, these burrs include a diamond-shaped pattern for aggressive material removal, which makes them suitable for heavy-duty applications.

– Selection of Shapes: Carbide burrs come in a variety of shapes – cylindrical, ball, oval, tree, plus more – to match your specific needs. These shapes provide versatility in tackling various tasks and reaching tight spaces.

To learn more about SH-7 Aluma Cut browse our new web portal